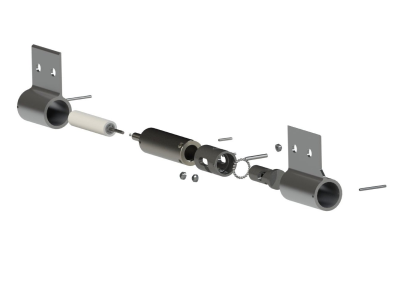

We specialize in creating and producing intricate mechanisms. Previous undertakings encompassed a diverse range of hinges, latches, and other mechanisms specifically developed for applications within aircraft interiors. We have an extensive expertise in devising systems and components for stowage bin and ceiling retention systems. Our internal design team consists of members with varied experiences, enabling us to adopt superior and more holistic approaches to addressing customer challenges. Collaboration between our engineering and manufacturing teams ensures that Harper products not only meet customer requirements but also undergo efficient production processes. Ongoing research and development efforts focus on enhancing mechanical and electronic interfaces, as well as the miniaturization of mechanisms.

Learn more

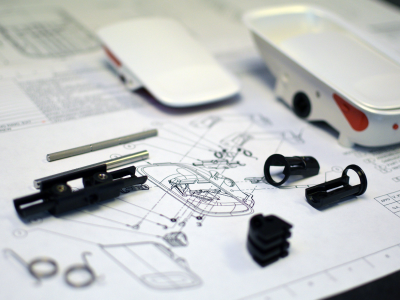

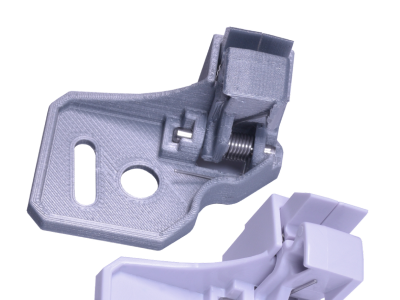

Harper Engineering places a strong emphasis on prototyping, aiming to address critical functionality requirements that drive part design. Prototyping methods utilized by Harper Engineering Co. include 3D printing, machining, and forming. The value Harper Engineering Co. finds in having a tangible part to test creates speed in part design and producibility in manufacturing.

Learn more

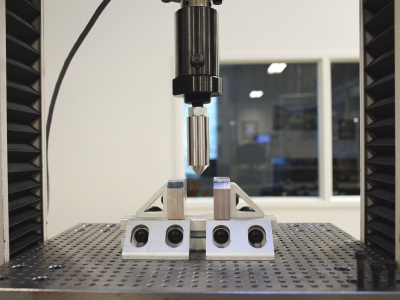

In addition to designing and manufacturing Harper products, our company takes on the crucial role of certifying these products after their development phase. We have comprehensive testing capabilities and resources that facilitate the certification process for aerospace components, encompassing lifecycle and strength testing. As our production team constructs test articles and fixtures, all of their work is overseen by in-house quality team that works closely with our engineers to ensure conformity. With a track record spanning five decades, Harper has successfully certified thousands of part numbers for flight, including both OEM designs and PMA parts.

Learn more

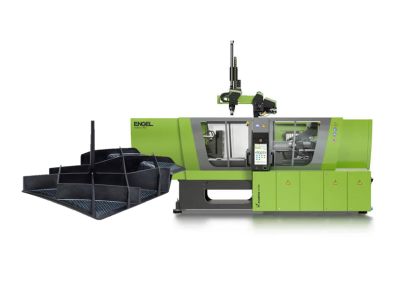

Harper Engineering Co. maintains cutting-edge equipment for injection molding and hybrid overmolding, a technique that has demonstrated its effectiveness in various automotive projects and is now being increasingly embraced by the aerospace engineering community. Our company aims to establish itself as a reliable and knowledgeable supplier of hybrid overmolded products, collaborating with customers on development initiatives, with plans to bring this capability into a full-scale production environment.

Learn more

Harper Engineering Co. has made substantial investments in various aspects of our machine shop, forming the foundation of our production capabilities. Recognizing the significance of our workforce, we provide internal training programs for machine operators and CNC programmers to ensure skilled and knowledgeable personnel. The shop is equipped with 3- and 4-axis vertical milling machines, 4-axis horizontal milling machines, twin-spindle turning centers, and a state-of-the-art Swiss-style turning center. Working with a range of materials such as plastics, aluminum, steel, and titanium, our shop actively incorporates collaborative robots (co-bots) into manufacturing processes and consistently seeks innovative approaches to optimize our manufacturing operations.

Learn more

We offer comprehensive mechanical solutions with a strong focus on value-added integration. Our company handles all assembly processes internally, following LEAN principles to optimize efficiency and effectively address changing customer needs. Whether it's small assemblies with a few components or large assemblies that are shipped in crates. And regardless of the production volume, whether it is 10 units per month or over 2,000 units per month, our team consistently delivers high-quality, conforming parts within the designated timelines.

Learn more

Having delivered over 100,000 composite assemblies, Harper Engineering Co. possesses the expertise and resources to manufacture durable and lightweight reinforced composite products. Our capabilities in thermoplastic composites encompass a wide range of polymers, including semi-crystalline and amorphous types, along with various reinforcements such as fiberglass, aramid, and carbon. Our company employs proprietary bonding technology to incorporate elastomer and metallic elements into innovative solutions. We have actively participated in international consortiums focused on advancing composite materials and processes, maintaining regular connections with composite professionals worldwide. Recognizing the challenges associated with procuring tooling for composite projects, we have made the strategic decision to incorporate tooling design and fabrication capabilities within our composite facility. This enables us to swiftly navigate the development phase of projects and implement solutions for our customers more efficiently than conventional methods allow.

Learn more

Harper Engineering Co. has expanded its offerings beyond hardware provision and now delivers integrated solutions to specific customers. A recent project exemplifies this capability, where we have designed and produced latching hardware, manufactured structural metal parts based on customer specifications, sourced a composite panel assembly from a different supplier, and seamlessly integrated, tested, and packaged the final assembly. The completed product was ready for installation on an aircraft for flight. This shows our company's abilities in engineering and manufacturing, but also our collaborative approach, working closely with our customers to overcome challenges and achieve elegant solutions.

Learn more